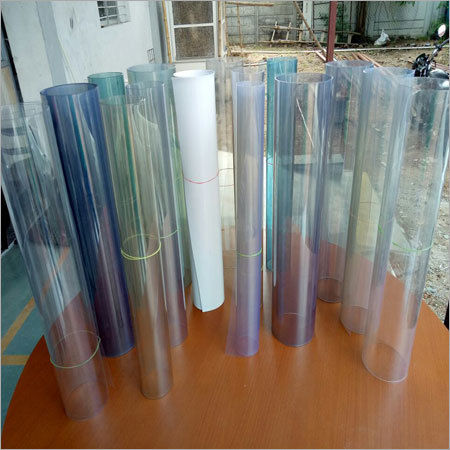

GAG PET SHEET

Product Details:

GAG PET SHEET Price And Quantity

- 50000 Piece

- 50000.00 - 100000.00 INR

Product Description

Grade Name: AVI-GAG PET

Grade Category: PTG 902

Composition: A/B/A structure, 100% Virgin

Roll outer diameter (mm):

500 max. (slit roll)

1200 max (jumbo roll)

Appearance: Transparent

Surface: Gloss/Gloss

Core I.D (mm): 76

Technical Specifications

| Test Parameters | Test Method | UOM | Standard Values |

| Thickness | ASTM - D 6988 | Micron | 0.200 to 1.200 ( 5%) |

| Width - rolls | ISO 4592 | mm | Slit rolls ( 1) |

| Jumbo rolls--( 2) | |||

| Gloss - @ 20 degree | ASTM D 2457 | ( % ) | 120 to 200 |

| Shrinkage @ 80 deg C for 15min (in MD, TD) | DIN 53377 | (%) | -5.0 to +2.0 |

| For thickness < 300 um | |||

| For thickness > 300 um | 1.33 to +0.02 | ||

| Density | ASTM-D 792 | gm / cm3 | 1.33 0.02 |

| Pendulum Impact Strength | ISO 8256 | KJ/M2 | > 300 |

| Dart Impact Failure wt. (Method B) (For thikcness = 300 um) | ASTM-D 1709 | gm | >350 |

| Tensile strength at Peak | ASTM - D 882 | Kg/cm2 | >400 |

| Tensile strength at Break | ASTM - D 882 | Kg/cm2 | >370 |

| Percentage Elongation at Peak | ASTM - D 882 | % | >2.5 |

| Percentage Elongation at Break | ASTM - D 882 | % | >3 |

| VSP | ASTM -D 1525 | oC | 70 2 |

| Surface Tension | ASTM-D 2578 | dyne/cm | N.A |

| Haze value | ASTM-D 4039 | % | 3 Max. |

| Thermoforming temperature (depends on thickness of film) |

| C | 120 - 160 |

| COF (Film to Metal) in M.D- S.F | ASTM - D 1894 |

| 50.5 |

| COF (Film to Metal) in M.D- D.F | ASTM - D 1894 |

| <0.50 |

| COF (Film to Film) in M.D- S.F | ASTM - D 1894 | --- | <0.50 |

| COF (Film to Film) in M.D- D.F | ASTM - D 1894 |

| 50.5 |

| Colour / Tone | Visual (Cust ref. Sample) | --- | As per customer requirements |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+